The Advancement of Aluminum Casting Techniques

Over the years, different innovative strategies have changed light weight aluminum spreading, substantially improving its performance and accuracy. The advancement began with standard sand spreading methods, which, while reliable, frequently led to inconsistencies in surface area finish and dimensional precision. The introduction of die casting in the mid-20th century allowed for faster manufacturing rates and enhanced top quality, as liquified aluminum was pushed into molds under high pressure, reducing porosity and boosting information.

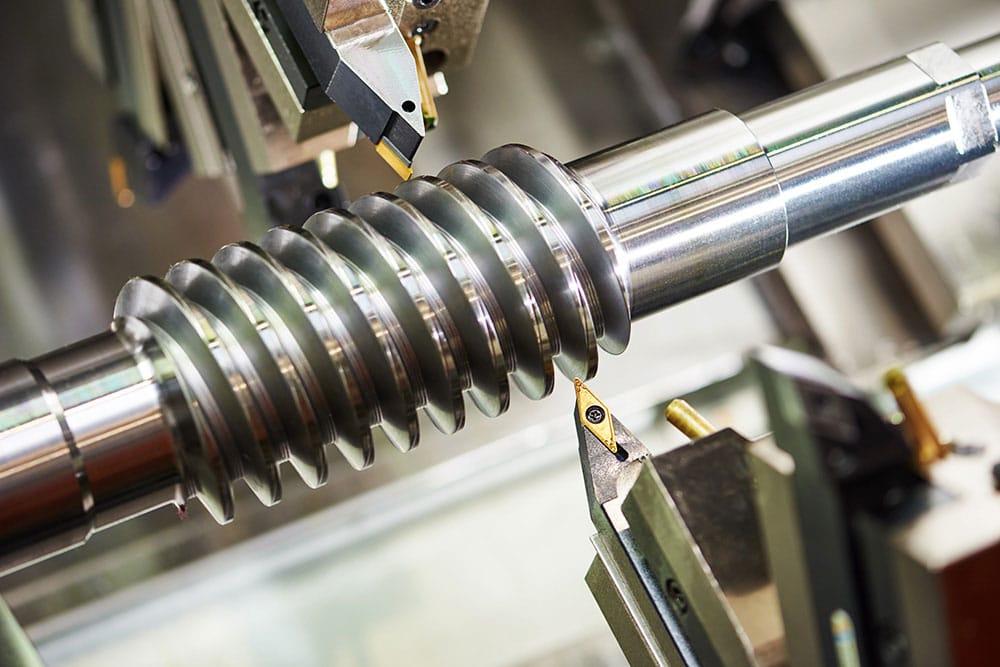

Additional innovations consisted of investment spreading, which provided even finer resistances and complex styles. The appearance of computer mathematical control (CNC) technology additionally reinvented mold style, enabling makers to develop intricate geometries with impressive accuracy. Today, additive production methods, such as 3D printing for developing mold and mildews, are on the rise, enabling fast prototyping and lowered preparations. Overall, these innovations have actually greatly impacted the aluminum casting process, satisfying a wider variety of industrial applications.

Advantages of Light Weight Aluminum in Manufacturing

Light weight aluminum has actually come to be a recommended material in manufacturing as a result of its one-of-a-kind mix of properties that boost efficiency and efficiency across numerous applications. Its lightweight nature enables for decreased power consumption during transportation and assembly, making it a cost-efficient selection for several industries. Additionally, aluminum exhibits exceptional rust resistance, making certain durability and reducing upkeep expenses.

ght proportion enables the production of tough yet light-weight elements, which is especially helpful in fields such as automobile and aerospace. Light weight aluminum additionally supplies exceptional thermal and electrical conductivity, making it ideal for a variety of commercial applications, consisting of electronics and warmth exchangers.

Additionally, aluminum's pliability permits detailed styles and simple manufacture, assisting in the manufacturing of complex forms without endangering structural honesty (Aluminum Casting Company). These benefits collectively add to light weight aluminum's expanding prominence in contemporary production procedures, driving development and improving product performance across a vast array of industries

Advancements in Light Weight Aluminum Casting Technology

As improvements in manufacturing technology remain to progress, technologies in aluminum casting have actually arised, boosting effectiveness and accuracy in production procedures. Amongst these technologies is the intro of advanced simulation software program, which permits suppliers to model the spreading procedure practically. This innovation allows the forecast of possible issues and optimizes mold layout, ultimately reducing material waste. In addition, the development of brand-new alloys has broadened the array of applications for light weight aluminum spreadings, improving mechanical residential or commercial properties and deterioration resistance.

Moreover, the fostering of 3D printing for mold production has transformed the spreading procedure, making it possible for the production of intricate geometries that were previously unattainable. This shift not only shortens lead times however additionally facilitates personalization in manufacturing. Overall, these advancements contribute considerably to the high quality and flexibility of aluminum castings, placing them as an important part in the future of producing innovation.

Effect On Manufacturing Efficiency and Cost Reduction

While the improvement of light weight aluminum spreading modern technologies presents numerous advantages, its most significant influence depends on improving manufacturing effectiveness and driving cost reduction. By simplifying the spreading process, producers can create intricate elements with higher rate and precision, substantially decreasing waste. Developments such as high-pressure die spreading and progressed mold and mildew layouts permit quicker cycle times and boosted dimensional accuracy, which reduce rework and scrap prices.

Additionally, the lightweight nature of aluminum adds to lower transportation costs and energy intake during production. Because of this, producers can attain significant economic situations of range, eventually reducing the per-unit expense of items. The ability to create high-grade castings in bigger quantities also makes it possible for business to react more quickly to market needs - Precision aluminum casting. These efficiency gains and price financial savings setting light weight aluminum casting as an affordable advantage in the manufacturing landscape, cultivating additional financial investments in modern technology and capacity development

Applications of Light Weight Aluminum Spreading Throughout Industries

The flexibility of aluminum spreading has actually resulted in its extensive fostering across various industries, taking advantage of the benefits of lightweight, long lasting parts. In the auto field, aluminum spreadings are made use of for engine blocks, transmission housings, and wheels, adding to fuel efficiency and performance. The aerospace sector uses aluminum castings for architectural elements, where weight reduction is necessary for trip efficiency. Additionally, the customer electronics industry leverages aluminum casting for gadget real estates and parts, enhancing durability while maintaining a sleek design. The construction sector also benefits from aluminum spreadings, utilizing them in home window structures and architectural aspects that call for both toughness and visual appeal. The medical area employs aluminum spreadings for tools and devices, where accuracy and dependability are extremely important. On the whole, the varied applications of light weight aluminum spreading throughout more info these sectors demonstrate its integral duty in advancing modern manufacturing techniques.

The Future of Aluminum Casting in Production

Development in aluminum casting innovation guarantees to reshape producing procedures in the coming years. Developments such as 3D printing and computer-aided style are streamlining manufacturing, enabling for a lot more intricate geometries and minimized waste. The integration of automation and robotics improves performance, enabling suppliers to generate premium parts with marginal human intervention. In addition, the growth of brand-new light weight aluminum alloys raises toughness and longevity, broadening the prospective applications in industries like aerospace and automobile.

As sustainability ends up being a top priority, recycling abilities within light weight aluminum casting will improve, minimizing environmental effect. The application of clever production strategies, including IoT and information analytics, will better enhance manufacturing workflows and upkeep methods. These improvements not only enhance operational performance however also lower expenses, making aluminum casting a much more attractive choice for makers. Inevitably, the future of light weight aluminum spreading holds promise for advancement, sustainability, and improved competition in the worldwide market.

Often Asked Concerns

What Precaution Are Associated With Aluminum Casting Processes?

Precaution in light weight aluminum casting processes include safety equipment, proper air flow, training on equipment usage, regular upkeep of machinery, monitoring of molten steel temperature levels, and adherence to safety and security protocols to stop crashes and guarantee worker well-being.

How Is Light Weight Aluminum Casting Environmentally Lasting?

Aluminum spreading is ecologically lasting because of its recyclability, power efficiency, and reduced greenhouse gas emissions. Using recycled light weight aluminum greatly lowers the energy needed for manufacturing, lessening environmental impact while preserving all-natural sources.

What Are Usual Flaws in Light Weight Aluminum Castings?

Typical issues in aluminum spreadings include porosity, shrinkage, misruns, cold shuts, and inclusions. These concerns can arise from improper temperature level control, insufficient mold layout, or contamination, influencing the general high quality and honesty of the last product.

Can Aluminum Spreading Be Reused?

Yes, aluminum spreading can be recycled. The reusing procedure decreases energy intake and ecological influence, enabling the reuse of aluminum in brand-new products. This sustainability element boosts its appeal in different production markets.

What Industries Largely Utilize Light Weight Aluminum Casting?

Aluminum casting is mainly made use of in the auto, aerospace, durable goods, and electronics industries. These fields benefit from aluminum's lightweight, corrosion-resistant properties, boosting item performance, performance, and toughness throughout various applications and components.

Over the years, various ingenious techniques have transformed light weight aluminum spreading, substantially improving its performance and accuracy. As advancements in producing technology continue to progress, advancements in aluminum casting have arised, boosting performance and precision in manufacturing processes. While the development of light weight aluminum casting technologies introduces many advantages, its most notable impact lies in enhancing manufacturing performance and driving price decrease. The aerospace market employs aluminum spreadings for structural elements, where weight decrease is vital for flight performance. Aluminum casting is ecologically sustainable due to its recyclability, power effectiveness, and minimized greenhouse gas exhausts.